Detailed Explanation of the WPC Decking Manufacturing Process

Detailed Explanation of the WPC Decking Manufacturing Process

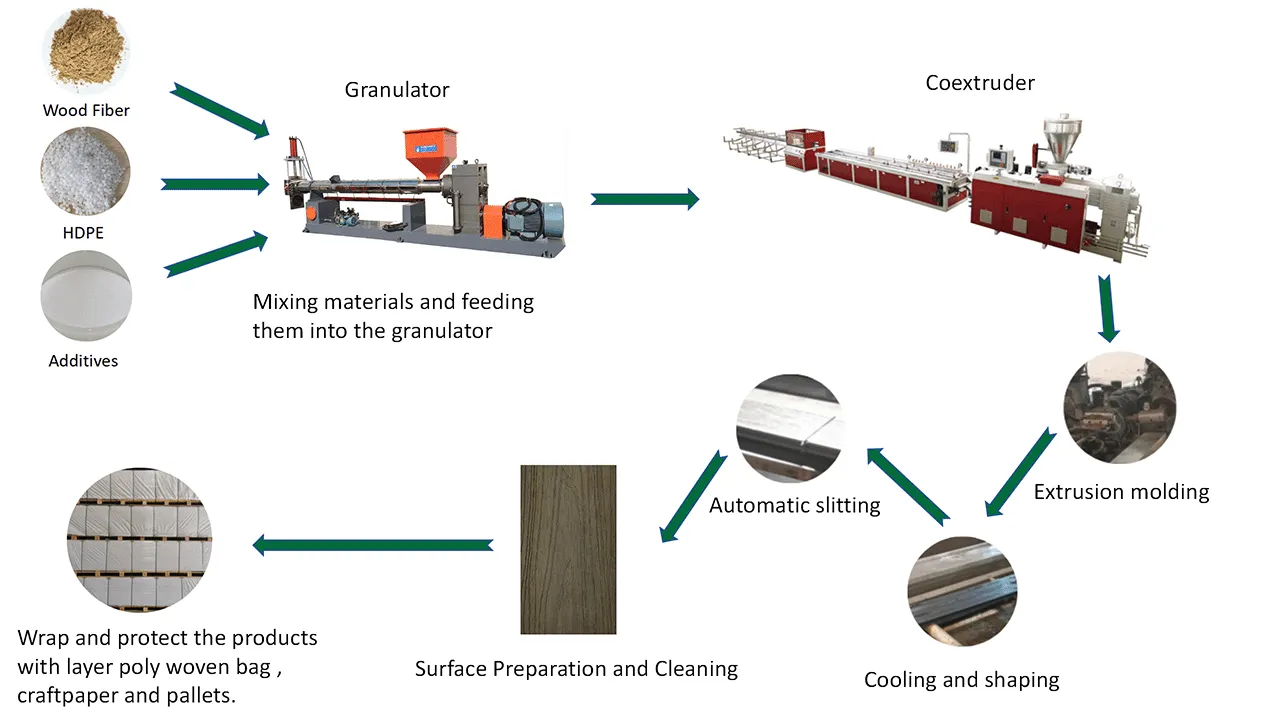

The production of WPC (wood-plastic composite) decking involves multiple complex technical steps, requiring precise control at every stage, from raw material selection to final product formation. The following is the main WPC decking manufacturing process:

- Raw Material Preparation and Proportioning

The main raw materials for WPC decking are wood fiber and plastic (typically recycled plastic), along with additives such as UV stabilizers, antioxidants, and colorants.

- Wood Fiber: Biomass materials such as sawdust, wood powder, bamboo fiber, and crop straw are commonly used as sources of wood fiber. Different wood fiber types affect the texture and performance of the final product.

- Plastic Matrix: Common plastics include polyethylene (PE), polypropylene (PP), and polyvinyl chloride (PVC). The choice of plastic directly affects the material’s weather resistance, UV resistance, and mechanical properties.

- Additives: To enhance the material’s performance, UV absorbers, preservatives, antioxidants, stabilizers, and colorants are often added to ensure stability in various environments.

Mixing Ratio: Typically, the ratio of wood fiber to plastic matrix in WPC ranges from 60%:40% to 70%:30%, and this ratio can be adjusted based on demand.

- Batching and Drying

- Batching: The raw materials must first be mixed in a specific ratio. This process is typically performed using a high-speed mixer to ensure a uniform blend of the wood fiber and plastic for subsequent processing.

- Drying: The wood fiber needs to be dried to remove any moisture. This is to prevent moisture from causing the material to swell or crack during the molding process. Drying is typically performed using a hot air dryer to ensure the moisture content of the wood fiber is within a reasonable range (typically 5%-10%).

- Extrusion

The core production process of WPC decking is extrusion, a process in which the raw materials are melted by heating and forced through a die to form the material.

- Screw Extruder: After mixing and drying, the raw materials are fed into the extruder. The extruder consists of a screw propeller and a heating zone. The screw propeller continuously pushes the mixture forward, while the heating zone heats and melts it.

- Temperature and Pressure Control: Controlling temperature and pressure is crucial in this process. Different types of plastics and wood fibers require different temperature conditions. Generally, the temperature is between 160°C and 220°C to ensure that the raw materials are fully melted but not decomposed.

- Molding: The molten mixture passes through the extruder’s die and is formed into the desired size and shape, typically in the form of strips or sheets. The mold can be designed with various surface textures to mimic the grain of natural wood or create other decorative effects.

- Cooling and Curing

Once the WPC mixture is extruded through the die, it needs to be cooled and cured to achieve a stable physical form.

- Cooling Tank: The extruded sheet is typically fed into a cooling trough, where a constant flow of cold water or air helps rapidly cool the product, ensuring it maintains the desired hardness and dimensions.

- Curing: The cooled sheet is brought into a curing chamber, where further air circulation and temperature regulation ensure the product’s internal molecular structure is fully stabilized. This process helps improve the mechanical properties of WPC decking, such as compressive strength and bending resistance.

- Cutting and Surface Treatment

- Cutting: After cooling and curing, WPC sheets are typically cut into the desired length and width. Automated cutting equipment allows for precise cutting according to customer requirements.

- Surface Treatment: The surface of WPC decking often requires further treatment to enhance its aesthetics and functionality:

- Texture Treatment: A heat press or roller coating process is used to impart a natural wood grain appearance to WPC decking. These textures can be customized to simulate various wood textures, such as oak and walnut.

- Spray Coating: Some manufacturers also use spray coating to apply a protective film to the surface of WPC sheets to improve UV and stain resistance.

- Anti-Slip Treatment: To enhance safety during use, the surface of WPC decking may be frosted or textured to increase its anti-slip properties, making it particularly suitable for use around swimming pools and outdoor trails.

- Inspection and Packaging

After production and surface treatment, WPC decking undergoes a series of quality inspections to ensure it meets relevant technical standards.

- Dimensional Inspection: Ensures that the thickness, width, and length of the decking meet design requirements.

- Performance Inspection: A series of performance tests are conducted, including weather resistance, UV resistance, water resistance, compressive strength, and abrasion resistance.

- Appearance Inspection: Ensures that the surface texture and color are uniform and free of defects such as scratches and cracks.

All qualified products are packaged, typically in plastic wrap or on wooden pallets, to ensure they are not damaged during transportation.

- Final Product and Application

Finally, WPC decking, as a high-performance outdoor flooring material, is delivered to customers for use in areas such as patios, balconies, terraces, and pool surrounds. Through this comprehensive manufacturing process, WPC decking offers excellent weather resistance, aesthetics, and low maintenance, making it an ideal choice for modern home and landscape designs.